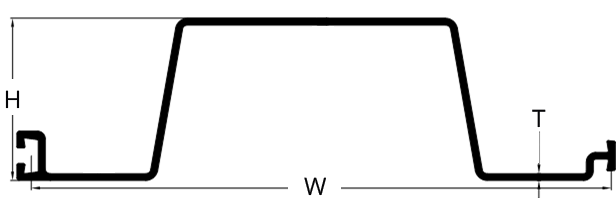

VINYL SHEET PILE PROFILE

Vinyl Sheet Piling or PVC Sheet Piles are an effective alternative to steel sheet piling for bulkheads, seawalls and cutoff walls. They are also superior to alternative materials like concrete and wood.

The main advantage of vinyl sheet piles is the superior corrosion resistance when exposed to seawater, where no oxidation occurs. Vinyl sheet piles are also highly resistant to marine borers which make it superior to wooden solutions.

Browse through ESC’s new range of sheet piles, manufactured in facilities in Europe.

Vinyl Sheet Piling also known as Synthetic Sheet Piling, Plastic Sheet Piles, PVC Sheet Piles are becoming increasingly popular for the construction of bulkheads, seawalls, cut-off and containment barriers due to their many advantage.

- Light Grey

- Dark Grey

- Clay

PESC Vinyl Sheet Pile

PESC-24 vinyl sheet pile, is a box profile that offers unmatched versatility and innovative characteristics that promote durability and excellent resistance to corrosion, impact, and ultraviolet rays. This product is designed to provide superior performance in a wide range of soil and environmental conditions, making it ideal for permanent applications. Additionally, its lightweight nature allows for easy handling and installation, reducing overall project time and labor costs. Vinyl sheet piles manufactured by Pietrucha ESC Inc. meet the following industry standards:

ASTM D8427-21: Standard Specification for Rigid Poly Vinyl Chloride (PVC) Exterior Profiles Used for Sheet Piling; USACE EM 1110-2-2502: US Army Corps of Engineers Specification for Flood Walls and other Hydraulic Retaining Walls; Other Local and National Specifications

PESC VINYL SHEET PILE PROFILE (MADE IN USA)

| Section | Width | Depth | Thickness | Cross Section Area | Section Modulus | Moment of Inertia | Allowable Moment | Ultimate Moment | Ultimate Stiffness | Impact Resistance ASTM 4226 P.A. | Weight | Cap Compatibility | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (W) | (H) | (T) | Per Pile | Per Wall | |||||||||

| in | in | in | in2 | in3/ft | in4/ft | ft-kips/ft | ft-kips/ft | ibf-in2 x106/ft | ft-lb/in | lb/ft | lb/ft2 | ||

| mm | mm | mm | cm2 | cm3/m | cm4/m | kNm/m | kNm/m | kNm2/m | kJ/m2 | kg/m | kg/m2 | ||

| PESC-24-6.4 | 24 | 9 | 0.25 | 11.2 | 14.6 | 69.5 | 3.9 | 7.8 | 26.2 | 1,500 | 6.99 | 3.5 | ESC 290 |

| 610 | 230 | 6.35 | 72.5 | 787 | 9,496 | 17.3 | 34.6 | 246.9 | 6.7 | 10.4 | 17.1 | ||

| PESC-24-7.6 | 24 | 9 | 0.30 | 13 | 17.4 | 80.9 | 4.6 | 9.2 | 30.5 | 1,500 | 8.13 | 4.06 | ESC 290 |

| 610 | 230 | 7.62 | 83.8 | 935 | 11,053 | 20.6 | 41.1 | 287.4 | 6.7 | 12.1 | 19.8 | ||

| PESC-24-9.0 | 24 | 9 | 0.35 | 14.8 | 20.1 | 92.2 | 5.4 | 10.7 | 34.8 | 1,500 | 9.21 | 4.61 | ESC 290 |

| 610 | 230 | 9.0 | 95.2 | 1,081 | 12,593 | 23.8 | 47.6 | 327.4 | 6.7 | 13.7 | 22.5 | ||

Comparison to Other Materials

| Type of Profile | Vinyl(PVC) | Steel | Concrete | Wood |

|---|---|---|---|---|

| Cost | ||||

| Low | High | Medium | Low | |

| Weight | ||||

| Light | Heavy | Very Heavy | Medium | |

| Resistance to Corrosion | ||||

| High | Low | N/A | N/A | |

| Resistance to Chemicals & Sea Water Environment | ||||

| High | Low | High | Low | |

| Resistance to Cracking & Spalling | ||||

| High | High | Medium | N/A | |

| Environmentally Friendly | ||||

| Yes | Yes | No | No | |

| Aesthetics | ||||

| High | Low | Medium | Medium | |

| Installation | ||||

| Easy | Easy | Difficult | Moderate | |

| Design Flexibility | ||||

| High | High | Moderate | High |

Material Standards

| ASTM | ISO | Min. Value / Range | |

|---|---|---|---|

| Density | |||

| ISO 1183-3 | 86-92 lb/ft | ||

| Flexural Strength | |||

| ASTM D790 | ISO 178 | 9572.49 psi | |

| Shore Durometer | |||

| ISO 868 | 75 Shore D | ||

| Modulus of Elasticity | |||

| ASTM D638 | ISO 178/527-2 | 379998.9 psi | |

| Tensile Strength | |||

| ASTM D638 | 6381.66 psi | ||

| Izod Impact Strength | |||

| ASTM D256 | 4.28 ft-lb/in2 | ||

| Charpy Impact Strength | |||

| ISO 179-1 | 14.27 ft-lb/in2 | ||

| Vicat Softening Temp. | |||

| ASTM D648 | ISO 306 | 170˚F |

USEFUL INFORMATION

send an inquiry

For all your inquiries/questions please fill-up the form

PRODUCT PHOTOS