Geotechnical piling for water-tightness

The tightness of locks in the vinyl sheet piling walls depends on the following factors:

- The shape of a lock, which can elongate or reduce the distance travelled by water.

- The width of a single vinyl sheet pile. The wider the section, the lower the number of locks per unit of length of the wall, e.g. by replacing 11.81in (300 mm) width piles with 23.86in (606 mm) piles, the leaking factor of the wall will be reduced by the factor of two.

- The PVC material is engineered with special compounds for resistance to harmful ultraviolet rays.

- The hydrostatic pressure affecting the wall. The higher the pressure, the lower the possibility of clogging of locks.

- The stress levels at the locks’ contact area. The higher the tightness and the pressure on the locks’ wall surfaces, the smaller the occurring gaps, therefore, rendering the flow of water through the lock limited.

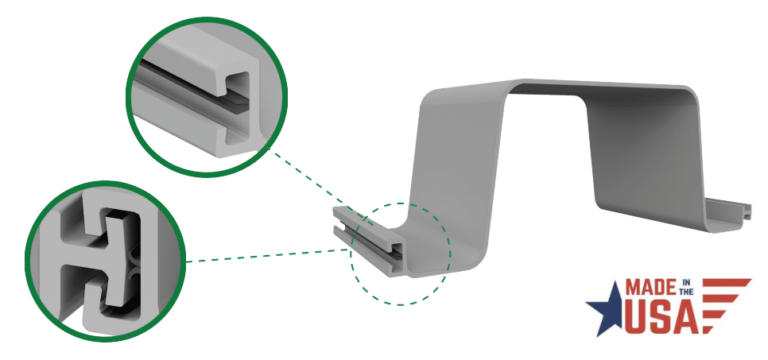

Ecoseal - Innovative Vinyl Sheet Piles with Integrated Gasket

Ecoseal is a state-of-the-art technology featuring an advanced gasket made of soft PVC. This technology improves the water-tightness of the cut-off wall after installation. Ecoseal is the ideal choice for hydrotechnical, civil engineering, and environmental protection projects that require low levels of hydraulic conductivity rates and durability.

Sheet piling for special purposes

Some strategic investment projects require of full water-tightness of the vinyl sheet piling constructions. In response to the needs expressed by customers, a specialized tightening solution based on the use of gaskets was specifically designed for this purpose. The gaskets are made out of soft PVC and co extruded into the locks during the manufacturing process. Their shape is determined by the type of the vinyl sheet piles.

ECOSEAL VINYL SHEET PILE

PRODUCT CHARACTERISTICS

- Material: Vinyl sheet piles provide a cost effective and sustainable alternative to traditional materials utilized in various commericial applications. Water Control, Cut-off and Containment and Flood Protection.

- Meets ASTM D8427-21

- Meets USACE EM 1110-2-2502

- Integrated Gasket Vinyl The soft PVC gasket is fused in the “Female Lock” of vinyl profile during the production process, creating a seamless and watertight connection. Gasket dimensions and shapes may vary depending on the application and soil conditions of project.

- Dimensions Available in various lengths to meet each applications requirements. Common lengths ranging from 8’ to 40’.

- Installation Vinyl sheet piles are compatible with traditonal driving equipment.

- Mandrel The use of the Mandrel is beneficial when used in conjunction with Ecoseal Vinyl Piles. It improves installation speed and greatly assists with ensuring design depth is attained

SPECIFICATIONS

| Section | Width | Depth | Thickness | Cross Section Area | Section Modulus | Moment of Inertia | Allowable Moment | Ultimate Moment | Ultimate Stiffness | Impact Resistance ASTM 4226 P.A. | Weight | Cap Compatibility | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (W) | (H) | (T) | Per Pile | Per Wall | |||||||||

| in | in | in | in2 | in3/ft | in4/ft | ft-kips/ft | ft-kips/ft | ibf-in2 x106/ft | ft-lb/in | lb/ft | lb/ft2 | ||

| mm | mm | mm | cm2 | cm3/m | cm4/m | kNm/m | kNm/m | kNm2/m | kJ/m2 | kg/m | kg/m2 | ||

| ECOSEAL PESC-24-6.4 | 24 | 9 | 0.25 | 11.2 | 14.6 | 69.5 | 3.9 | 7.8 | 26.2 | 1,500 | 6.99 | 3.5 | ESC 290 |

| 610 | 230 | 6.35 | 72.5 | 787 | 9,496 | 17.3 | 34.6 | 246.9 | 6.7 | 10.4 | 17.1 | ||

| ECOSEAL PESC-24-7.6 | 24 | 9 | 0.30 | 13 | 17.4 | 80.9 | 4.6 | 9.2 | 30.5 | 1,500 | 8.13 | 4.06 | ESC 290 |

| 610 | 230 | 7.62 | 83.8 | 935 | 11,053 | 20.6 | 41.1 | 287.4 | 6.7 | 12.1 | 19.8 | ||

| ECOSEAL PESC-24-9.0 | 24 | 9 | 0.35 | 14.8 | 20.1 | 92.2 | 5.4 | 10.7 | 34.8 | 1,500 | 9.21 | 4.61 | ESC 290 |

| 610 | 230 | 9.0 | 95.2 | 1,081 | 12,593 | 23.8 | 47.6 | 327.4 | 6.7 | 13.7 | 22.5 | ||

ESC ECOSEAL SHEET PILING WITH GASKETS (At client’s request)

Vinyl sheet pile profiles are manufactured with an integrated gasket, which ensures 100% water-tightness of the locks provided that they are properly installed.

TECHNICAL SUPPORT & SERVICES

At ESC, we are committed to providing comprehensive technical support and services to ensure the successful implementation of Ecoseal vinyl sheet piles in your projects. Our goal is to assist you at every stage, from preliminary design to post-installation support, ensuring that you achieve the best possible outcomes. Here are the key services we offer:

PRELIMINARY DESIGN

Our experienced engineering team will work with you to develop an initial design tailored to your specific project requirements. We take into consideration factors such as site conditions, environmental impact, and project goals to create a customized solution that meets your needs.

GEOTECHNICAL ANALYSIS

Understanding the soil and ground conditions is crucial for the success of any project. We offer thorough geotechnical analysis to assess soil stability, permeability, and other key parameters. This analysis helps in selecting the most appropriate and effective Ecoseal profiles for your project.

OPTIMAL PROFILE SELECTION

Based on the preliminary design and geotechnical analysis, we will recommend the optimal Ecoseal profile for your project. Our goal is to ensure that you achieve maximum performance and durability, while also considering cost-effectiveness and ease of installation.

ON-SITE TECHNICAL ASSISTANCE

Our technical experts are available to provide on-site support during the installation of Ecoseal sheet piles. This includes overseeing the installation process, ensuring compliance with design specifications, and addressing any technical challenges that may arise. Our presence on-site helps to ensure a smooth and successful implementation.

INSTALLATION CONSULTATIONS

We offer detailed consultations to guide you through the installation process. This includes advice on best practices, recommended equipment, and methods for different soil conditions. Our aim is to ensure that your installation is efficient, safe, and meets all project requirements.

LUNCH & LEARN SESSIONS

We understand the importance of education and training for project stakeholders. Our Lunch & Learn sessions are designed to provide valuable insights into the benefits and applications of Ecoseal vinyl sheet piles. These sessions are an excellent opportunity for you and your team to learn about the latest advancements and ask questions in an informal setting.

WORKSHOPS

For a more hands-on learning experience, we offer workshops that cover all aspects of using Ecoseal sheet piles. These workshops include practical demonstrations, interactive discussions, and detailed explanations of the installation process. Participants will gain a deeper understanding of the technology and how to effectively implement it in their projects.

ONGOING SUPPORT

Our commitment to your project does not end with the installation. We provide ongoing support to ensure the long-term success and performance of Ecoseal sheet piles. This includes regular maintenance advice, troubleshooting assistance, and updates on any new developments or improvements in our products.

For more information about our technical support and services, or to schedule a consultation, please contact our customer service team. We are here to assist you with all your project needs and ensure that you achieve the best results with Ecoseal vinyl sheet piles.

By offering a comprehensive range of technical support and services, ESC ensures that you have all the resources and expertise needed to successfully integrate Ecoseal vinyl sheet piles into your projects. Our dedication to quality, innovation, and customer satisfaction makes us the ideal partner for your construction and environmental protection needs.