ESC VINYL SHEET PILES

Vinyl Sheet Piles or PVC Sheet Piles are an effective alternative to steel sheet piling for bulkheads, seawalls and cutoff walls. They are also superior to alternative materials like concrete and wood. The main advantage of vinyl sheet piles is the superior corrosion resistance when exposed to seawater, where no oxidation occurs. Vinyl sheet piles are also highly resistant to marine borers which make them superior to wooden solutions. Browse through ESC’s new range of sheet piles, manufactured in facilities in Europe in partnership with the Pietrucha Group. Soon to be manufactured in the USA. Vinyl Sheet Piling also known as Synthetic Sheet Piling, Plastic Sheet Piles, PVC Sheet Piles are becoming increasingly popular due to:

- 50+ year design life and warranty – Due to their superior corrosion resistance, ESC Vinyl Sheet Piles can be used with confidence in their structural integrity and appearance even after 50 years.

- Cost Efficiency – both from installation and long term cost savings due to superior corrosion resistance and lower price per unit foot of material.

- UV Resistance – The PVC material is engineered with special compounds for resistance to harmful ultraviolet rays.

- No toxic coatings – No coatings are required, which may be detrimental to the environment.

- Not Affected by Marine Borers – Small mollusks or crustaceans in the ocean can cause devastating effects over a period of time to traditional timber piling. Vinyl Sheet Piling offers an attractive alternative that is unaffected by these organisms.

- Easy Installation – Compared to steel sheet piles, vinyl sheet piles can be up to 100 times lighter per square foot making it much easier to handle. Driving can also be completed under certain conditions by pressing down with an excavator or a impact vibrohammer.

- Carbon Emissions – Significantly lower than steel solutions.

Plastic Sheet Pile Typical Applications

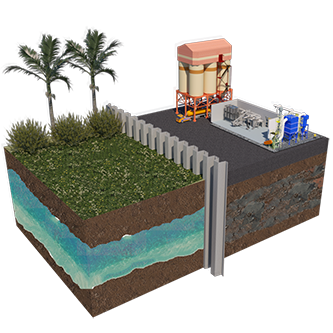

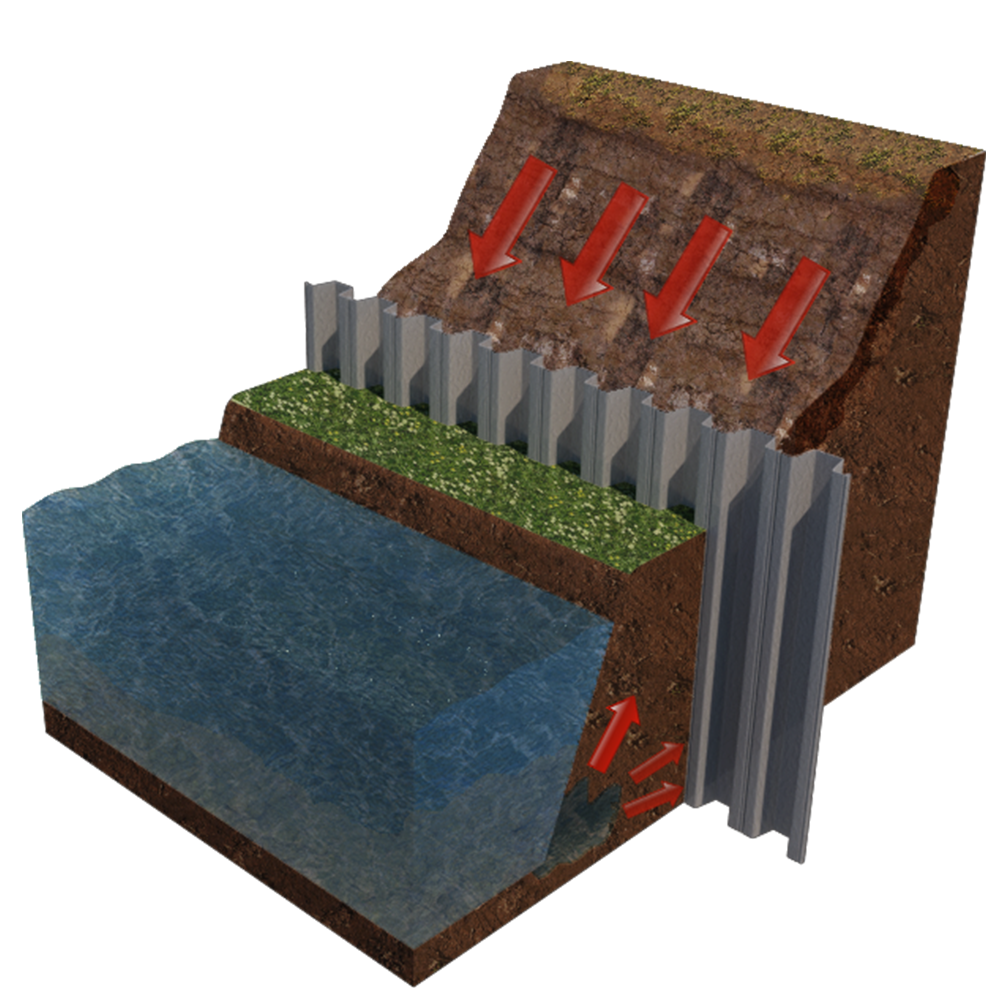

ESC Vinyl PVC Sheet Piles can be utilized for flood protection structures such as Flood Walls or Levees, Stabilization of Dams, Protection of Piping.

ESC Vinyl Piles are an alternative solution to common materials for containment and cut-off applications due to there chemical and corrosive resistance. The use of Ecoseal sheetpile with its co-extruded gasket will further enhance the cut-off performance. Application include but are not limited to:

- Groundwater cut-off

- Chemical containment

- Fluid Seepage Barriers

- Protection of Foundation Structures

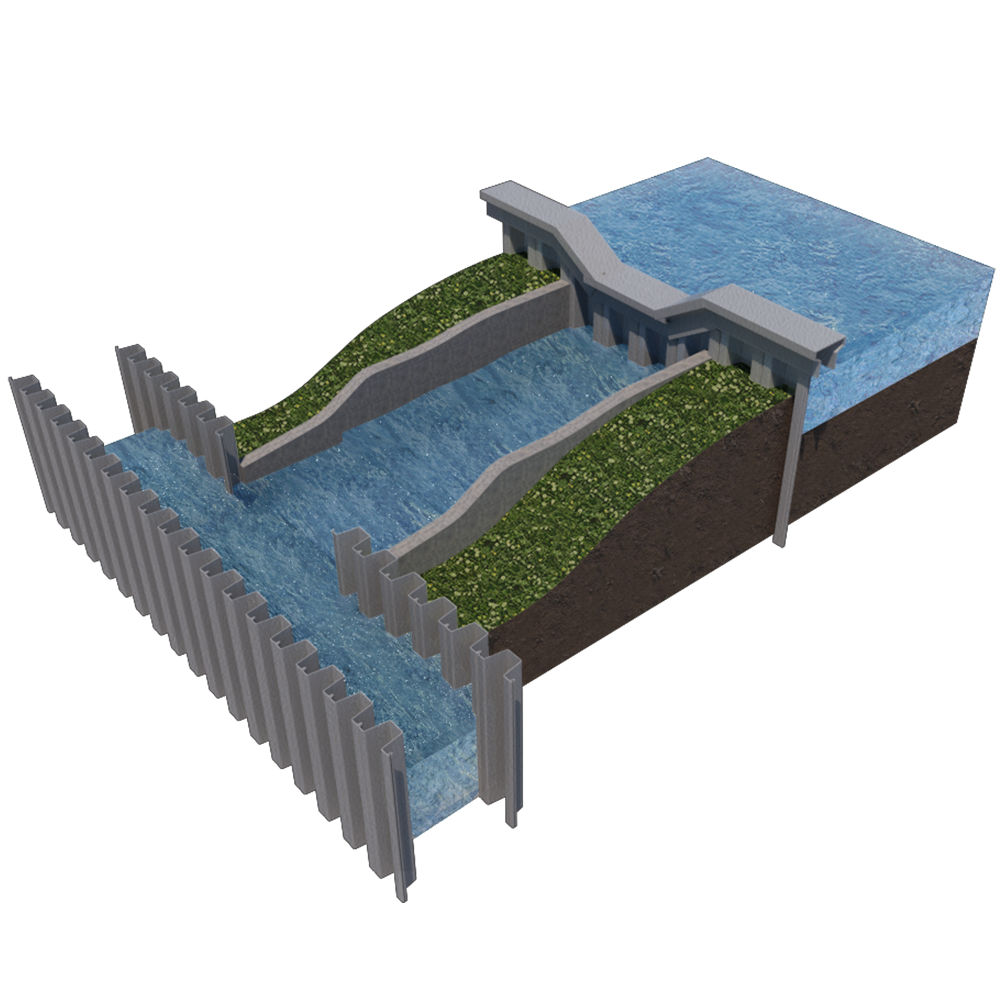

Vinyl PVC Sheet Piles can be utilized for water control structures that function by altering the flow of water in a pond, drainage channel or stream. ESC sheet piles have been utilized for water control applications for decades. Examples of utilizing vinyl sheet piles relevant to water control systems include:

- Baffle Walls for water or waste water flow control

- River Weirs

- Channel Linings for agricultural applications

- Pond Linings

- River Diversions

- Mining Drainange Systems

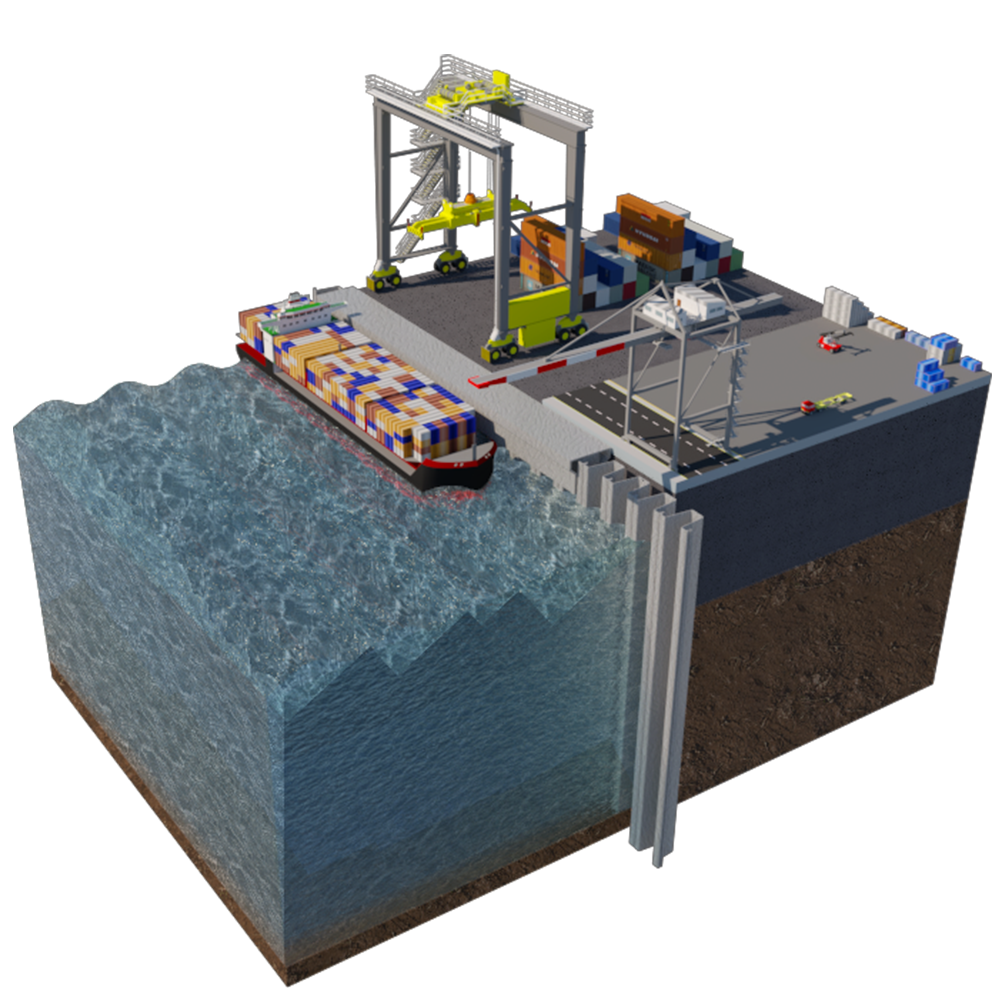

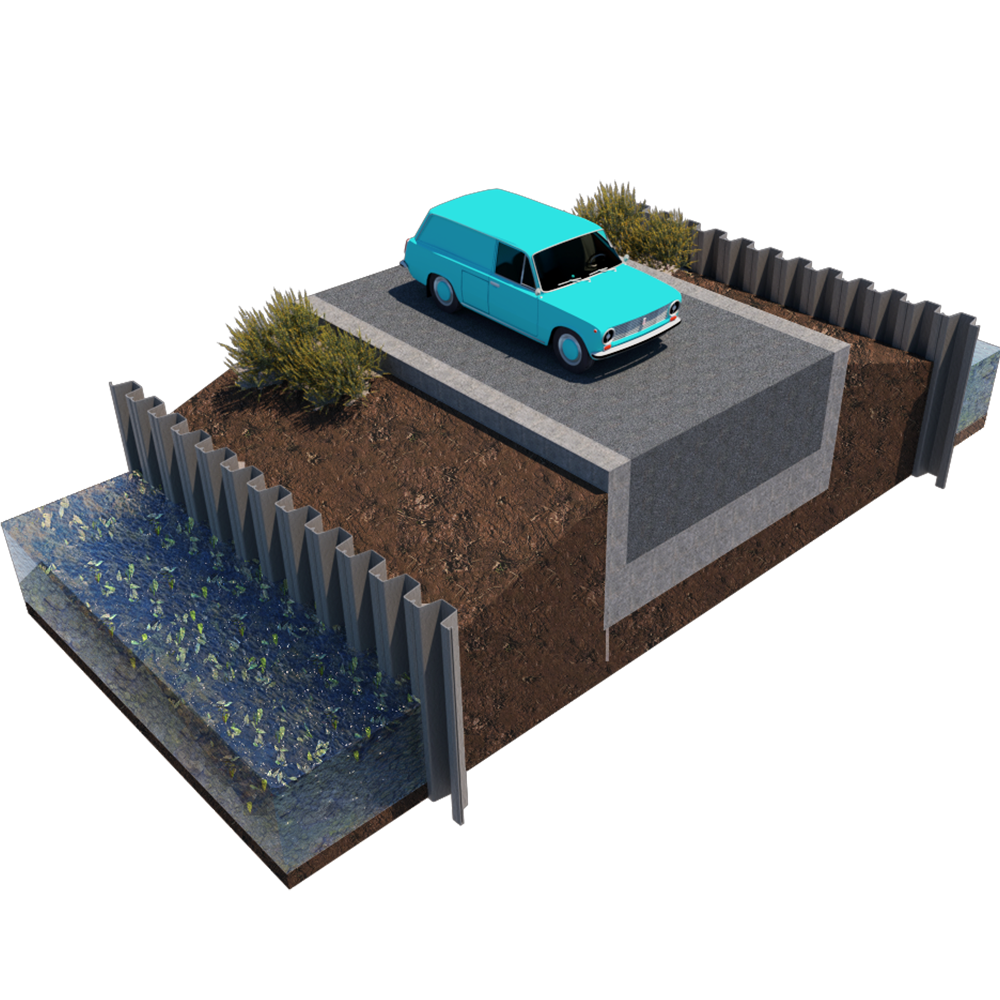

Over the last 35 years ESC has been delivering sheet piling solutions to marine structures. Vinyl PVC Sheet Piles provide an excellent option for a long lasting structural solution due to their superior corrosion resistance, aesthetic finish and lightweight profile for easy handling and installation. The marine

applications include:

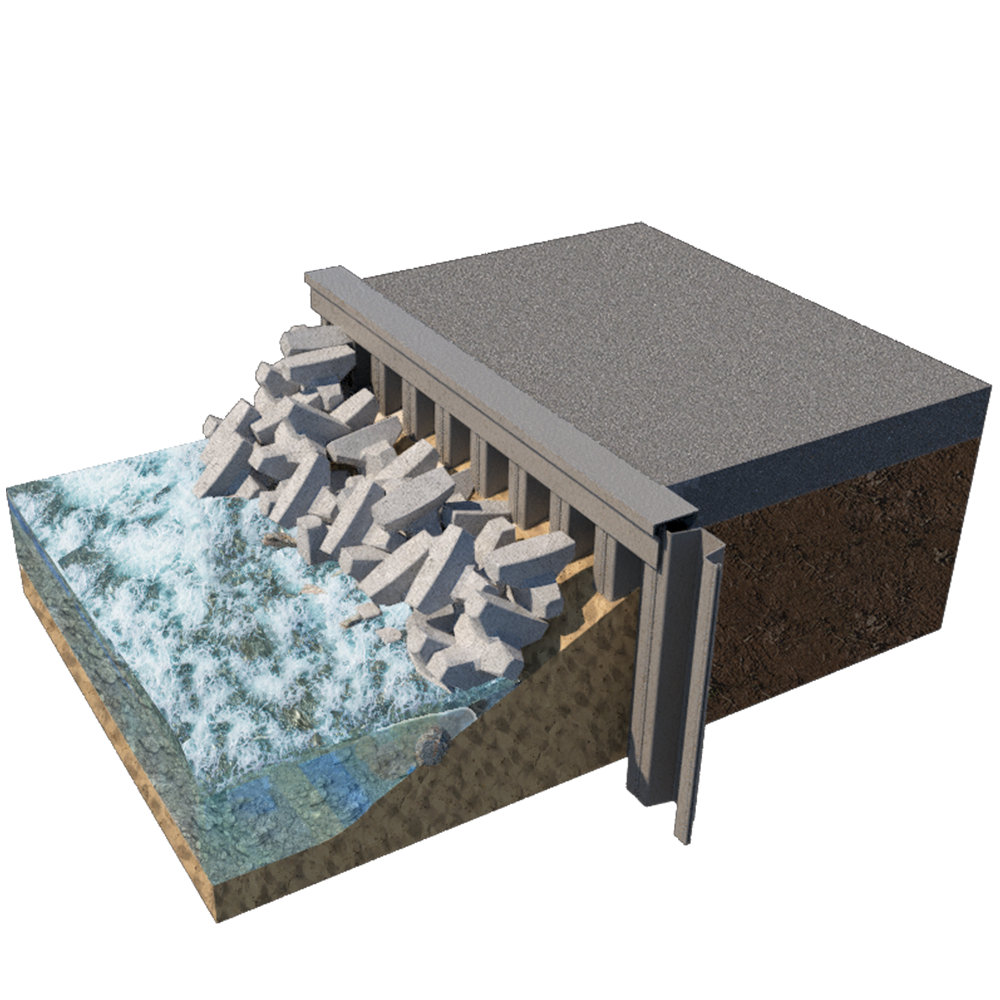

- Marine Bulkheads & Seawalls

- Tide Walls

- Breakwaters

- Wave Breaks

- Jetty Structures

- Groins

- Scour Protection and Erosion Control

- Retaining Walls

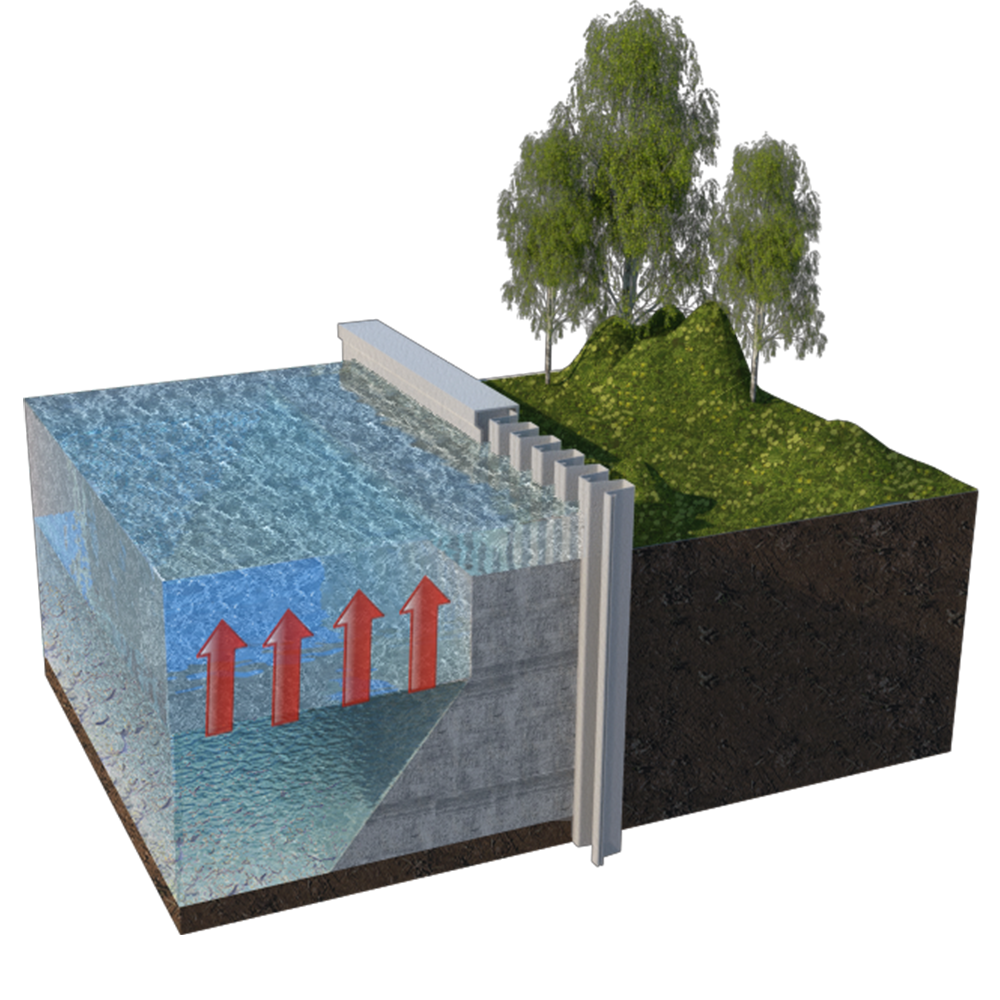

Vinyl PVC Sheet Piles can be utilized for flood protection structures:

- Flood Walls / Flood Level

- Stabilization of Dams

- Protection of Piping

Vinyl Sheet Piles are frequently utilized to replace old corroded sheet pile structures as a superior alternative with superior corrosion resistance that is environmentally friendly.

PRODUCT PHOTOS

ESC Vinyl Sheet Piling with Gaskets

Geotechnical piling for special purposes

The tightness of locks in the vinyl sheet piling walls depends on the following factors:

- The shape of a lock, which can elongate or reduce the distance traveled by water;

- The width of a single vinyl sheet pile. The wider the section, the lower the number of locks per unit of the length of the wall, e.g. by replacing 11.81in (300 mm) width piles with 23.86in (606 mm) piles, the leaking factor of the wall will be reduced by the factor of two;

- The PVC material is engineered with special compounds for resistance to harmful ultraviolet rays

- The hydrostatic pressure affecting the wall. The higher the pressure, the lower the possibility of clogging of locks;

- The stress levels at the locks’ contact area. The higher the tightness and the pressure on the locks’ wall surfaces, the smaller the occurring gaps, therefore, rendering the flow of water through the lock limited.

Some strategic investment projects require a guarantee of full water-tightness of the vinyl sheet piling constructions. In response to the needs expressed by customers, a specialized tightening solution based on the use of gaskets specifically was designed for this purpose.

The gaskets are made out of soft PVC and co-extruded into the locks during the manufacturing process. Their shape is determined by the type of vinyl sheet piles.